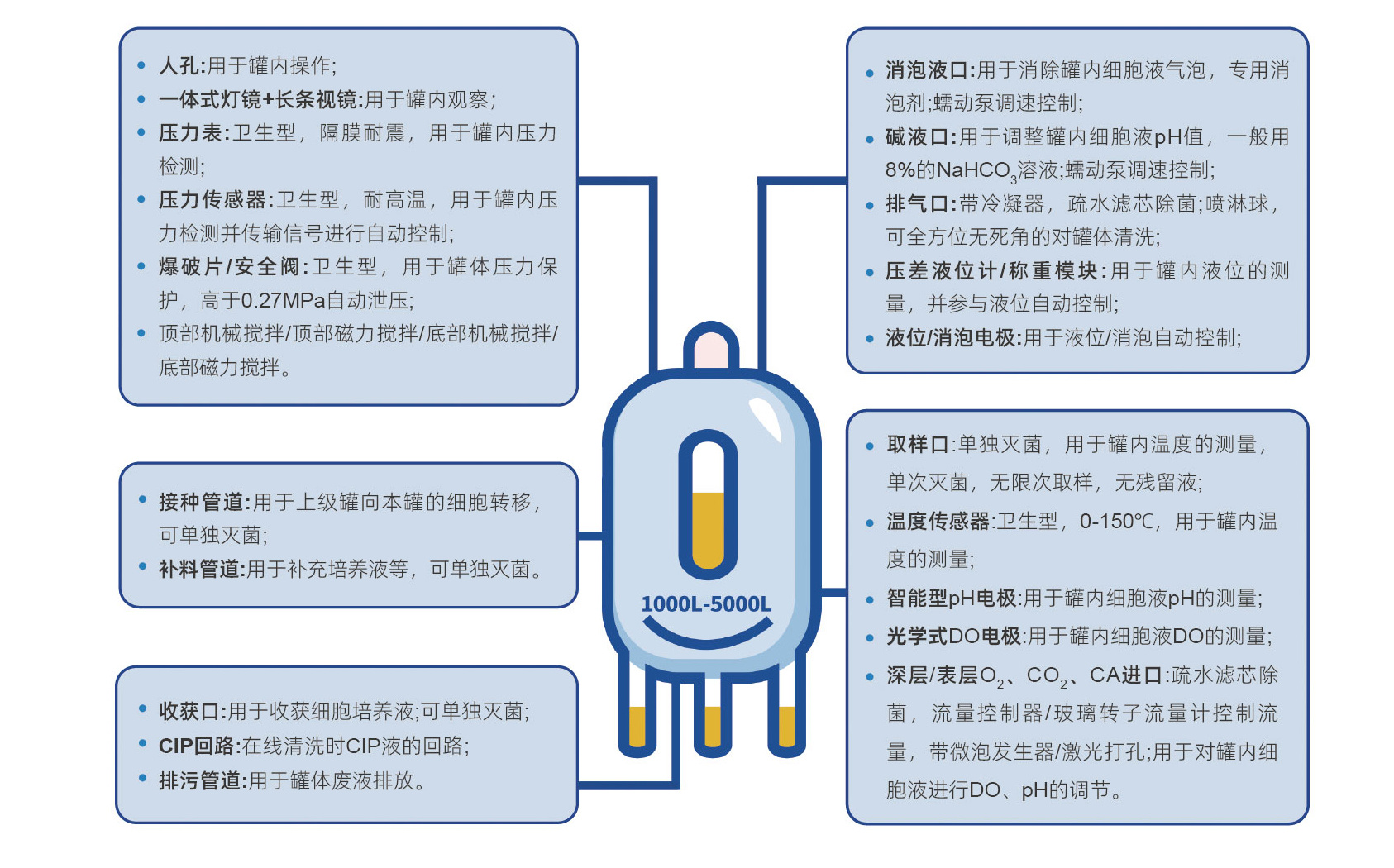

1000L-5000L Modular Engineered Bioreactor

| ● Mammalian and insect cell culture | ● Suspension cell culture |

| ● Development of production processes and sample production for vaccines, recombinant proteins, and monoclonal antibodies | ● Process development, optimization, and identification |

| ● Scale UP amplification research | ● Pilot production and large-scale production |

| ● Develop process strategies using batch, flow, continuous, or infusion modes |

- Product Features

- Product Parameters

- Control Accuracy and Range

- Product Disassembly Diagram

- Case Presentation

-

● One-button automatic sterilization technology with cold spot temperature measurement to ensure sterilization reliability

● Modular design for seamless integration between reactors

● CFD-based fluid simulation stirring system ensures efficient mixing

● Bidirectional temperature control for cooling and heating, with self-adaptive PID, unaffected by ambient temperature. Temperature control accuracy ±0.1°C, no overshoot during rapid temperature rise

● Dual-mode dissolved oxygen control with oxygen and compressed air, auto-switching to accommodate DO control in different growth stages

● Unlimited sampling for one-time sterilization, with no residual liquid discharge, ensuring safety and reliability

● Preset process parameters, real-time data, fault alarms, login/logout records, and operation logs are permanently stored and can be accessed for analysis at any time

● Internet connectivity enables remote monitoring and control via mobile or computer

● Self-inspection during startup and cell culture processes ensures stable control of cell culture

● Pre-set automatic restart function; When power is restored after an outage, the equipment will automatically resume the pre-failure control state

● Supports timed startup, shutdown, and automatic adjustment of control data

● Equipped with curve recording functionality

● Simple, quick, and safe pipeline operations

● Standard modular design with components and PLC software library

● Validated aseptic design and stability ensure process reliability

● Proven hardware design and control software

● Complies with cGMP and FDA requirements

-

● Working volume: 1000L-5000L (total volume 1300L-6000L) ● Tank material: 316L stainless steel tank body ● Tank structure: with jacket and insulation layer ● Polishing requirement: Inner polishing ≤ 0.4 μ m ● Sterilization method: Fully automatic online sterilization, with a cold spot thermometer to ensure sterilization effectiveness ● Temperature control: electric heating, cold water heat exchanger cooling ● Mixing method: Multiple mixing methods are available, and different mixing methods are chosen for different cultivation processes ● Surface intake: Surface compressed air intake ● Deep intake: including oxygen, carbon dioxide, and compressed air three way intake ● Intelligent pH electrode, optical DO electrode ● Three sets of peristaltic pumps, adjustable from 0-100rpm, disposable ● Top integrated light mirror, side long strip mirror ● Safety guarantees such as bursting discs and pressure relief valves ● Siemens PLC control, 12 "touch screen human-machine interaction ● Control cabinet: 304 stainless steel control cabinet, personalized design, small footprint, easy maintenance, beautiful appearance -

● Temperature control range: 20-40 ℃, control accuracy ± 0.1 ℃ ● PH control range: 2-12, control accuracy ± 0.02 ● DO control range: 0-100% air saturation, control accuracy ± 5% ● Speed control range: 0-200rpm, control accuracy ± 0.1rpm ● Pressure control range: 0-1.5bar, control accuracy ± 0.1bar -

Official account

Wuxi Address: 699 Zhide Avenue, Xinwu District, Wuxi City

Suzhou Address: Entrance A, 1F, Zhanhua Science and Technology Building, No. 8 Pangyang Road, Wujiang District, Suzhou City, Jiangsu Province

Copyright:© 2025 CNBG ToCell (Wuxi) Biotechnology Co., Ltd. Powered by:www.300.cn SEO