Disposable Bioreactors

| ● Mammalian and insect cell culture | ● Suspension cell culture |

| ● Pilot production | ● Process development, optimization, and identification |

| ● Scale UP amplification research | ● Seed production and amplification |

| ● Development of production processes and sample production for vaccines, recombinant proteins, and monoclonal antibodies | |

- Product Features

- Product Parameters

- Control Accuracy and Range

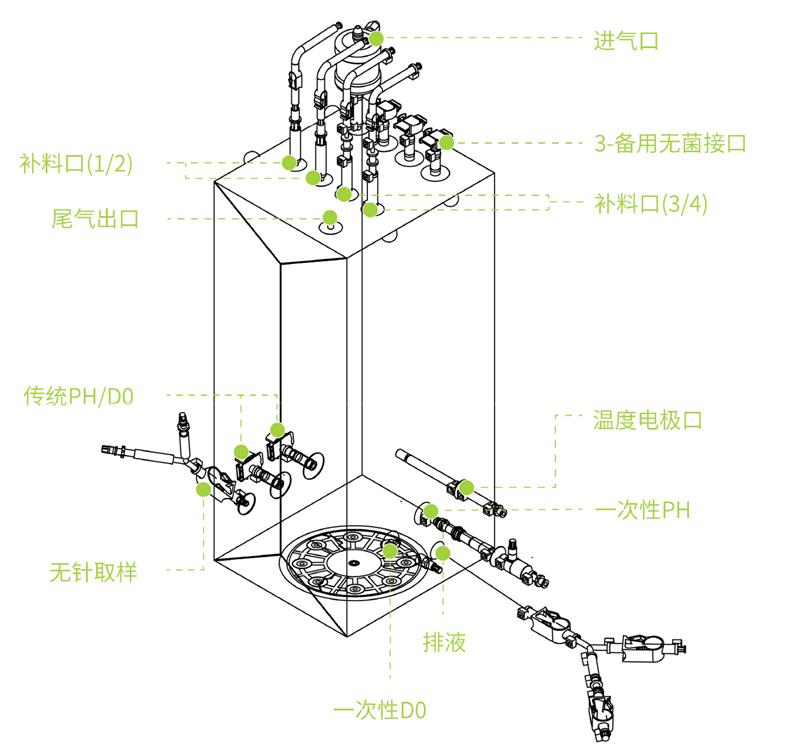

- Product Disassembly Diagram

- Case Presentation

-

● CFD-based fluid simulation stirring system ensures efficient mixing

● Dual-mode dissolved oxygen control with oxygen and compressed air, auto-switching to accommodate DO control in different growth stages

● Bottom motor drive for easy disassembly and reassembly

● Large single-door design for easy loading of reaction bags

● Double-layer jacket with water circulation for the tank and door, enhancing temperature uniformity

● Supports traditional and disposable pH/DO electrodes, with optional dual-electrode setup

● Highly integrated temperature control system with over-temperature protection, first heat-up rate under 0.2°C, control accuracy of ±0.1°C

● CFD analysis confirms the performance of the disposable bioreactor, showing excellent oxygen transfer, mixing efficiency, low shear, and even heating, meeting cell culture environmental needs

● Preset process parameters, real-time data, fault alarms, login/logout records, and operation logs are permanently stored and can be accessed for analysis at any time

● Internet connectivity enables remote monitoring and control via mobile or computer

● Self-inspection during startup and cell culture processes ensures stable control of cell culture

● Pre-set automatic restart function; When power is restored after an outage, the equipment will automatically resume the pre-failure control state

● Supports timed startup, shutdown, and automatic adjustments of control data

● Equipped with curve recording functionality

● Simple, quick, and safe pipeline operations

● Standard modular design with components and PLC software library

-

● Working volume: 50L-50OL ● Tank material: Supporting container: 304ss stainless steel ● Cultivation container: disposable bioreactor bag ● Tank structure: with jacket and insulation layer ● Temperature control: electric heating, cold water heat exchanger cooling ● Mixing method: single-layer bottom magnetic stirring ● Surface intake: Surface compressed air intake ● Deep intake: including oxygen, carbon dioxide, and compressed air three-way intake (optional) ● Intelligent pH electrode, optical DO electrode, disposable electrode, dual electrode (optional) ● Four sets of peristaltic pumps, adjustable from 0-100rpm, disposable ● Bag: Customizable, customized bag body with cell technology ● Siemens PLC control, 12 "touch screen human-machine interaction ● Control cabinet: 304 stainless steel control cabinet, personalized design, small footprint, easy maintenance, beautiful appearance -

● Temperature control range: 20-40 ° C; control accuracy ± 0.1 ° C ● PH control range: 2-12; Control accuracy ± 0.02 ● DO control range: 0-100% air saturation; Control accuracy ± 5% ● Speed control range: 0-200rpm; Control accuracy ± 0.1rpm -

Disposable bioreactor bag

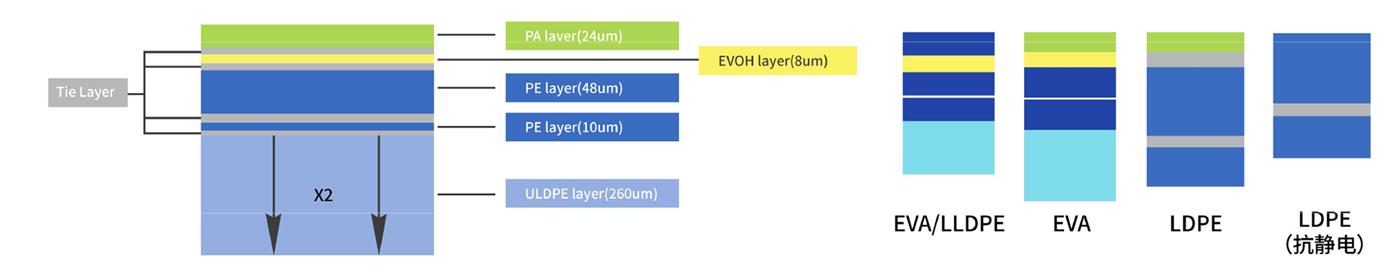

Disposable bioreactor bags are widely used in fields such as biopharmaceuticals, cell therapy, vaccine production, genetic engineering, and microbial fermentation, and can meet the needs of various biological reactions. Adopting 5-layer composite material high purity co extruded film material, the structure is composed of PA layer (polyamide nylon), EVOH layer (ethylene/vinyl alcohol copolymer), PE layer (polyethylene) and ULDPE layer (ultra-low density polyethylene), which have good chemical inertness, high-performance mechanical strength, extremely high puncture and tear resistance, and ultra-low precipitation level. Compliant with industry standards and strict change control management, and can be deeply customized according to customer needs.

(1) Stirring, pH/DO electrodes, inlet and outlet gases, and inlet and outlet liquids are all designed for one-time use or sterile docking.

(2) All materials meet GMP requirements for leaching and precipitation, toxicological assessment, and stability.

(3) Ensure the mixing effect and ventilation efficiency of the mixer.

Membrane structure

(仅为结构示意图)

不锈钢罐体

Official account

Wuxi Address: 699 Zhide Avenue, Xinwu District, Wuxi City

Suzhou Address: Entrance A, 1F, Zhanhua Science and Technology Building, No. 8 Pangyang Road, Wujiang District, Suzhou City, Jiangsu Province

Copyright:© 2025 CNBG ToCell (Wuxi) Biotechnology Co., Ltd. Powered by:www.300.cn SEO